End Cap for Multimode Fibers

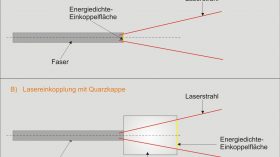

When coupling of the laser beam, it is focused into the fiber core, while a high power density occurs on the front surface. Although the anti-reflective (AR) coating of this surface reduces the Fresnel loss, it does not tolerate high power density even despite a large core diameter. A fiber end face without AR coating allows greater performance, but simultaneously leads more heat into the connector on the output side. This must be considered in terms of heat management.

For small fiber core Diameters with high power density dominate fiber connectors with a cylindrical end cap made of quartz glass currently. This end cap is larger than the fiber core and is spliced to the optical fiber. In doing so, the laser beam is focused onto the fiber core via the end surface of the quartz cap, where, at the same laser power, the power density is significantly lower. When, for instance, coupling 500 W of laser power in a 200 micron fiber, a 3 mm long quartz cap changes the energy density at the surface by the factor of 30. This allows the use of AR coating also in the kilowatt range. The method requires robust and low-loss splicing that guarantees a high damage threshold at the border between the end cap and the fiber.

Technical Specifications

| Connector Type | D80, HP-SMA |

| End Cap-Diameter | 1,5 mm |

| End Cap-Length | 3,8 mm - for fiber core 100µm und 200µm 2,5 mm - for fiber core > 400µm |

| End Cap-Material | Fused Silica |

| AR-Coating optional | Only by L 3,8mm AR<0.7% in range of 750nm and 1070nm, also AR <30% (Transmission >70%) at 670nm +-15nm |

| Coating absorption: | <15ppm@1064nm |

| Fiber Type circular | 100/660, 200/500, 400/480, 600/720, 800/880, 1000/1100 |

| Fiber Type non circular | 100x100, 200x200, 400x400 |

Gallery